HYDRAULIC PRESS BRAKE MACHINE

Maruti Hydraulic Press Brake are designed and developed through years of experience in sheet metal working machineries. Maruti Hydraulic Press Brake are developed by keeping latest technology in mind. Both cylinders are mounted on back side of Press Brake and are synchronized for parallels between ram and table, by providing mechanical links with cylinder.

The heavy duty steel construction frame is so designed to absorb heavy shocks o0f overload. All welding are properly machined for best weld joints. The electric control panel is fixed on side at conventional place for easy reach of operator. It includes foot button pendant and foot switch. Standard “V” block and “V” punch are manually operated black gauge system which is front operated are supplied as a standard accessories.

Hydraulic components are of reputed make like Videkers, Rexorth, Dowty, Yuken, Polyhydron, etc. we have become due to our premium quality products one of the leading NC Press Brake Manufacturers in India. We have also created a reputation in the hearts of our customers as the finest Mechanical Press Brake Exporters in India.

PRODUCT OVERVIEW

STANDARD FEATURE

- Electric motor

- Control panel with selection of INCH-ONCE-AUTO mode of operation

- Foot switch

- Fine stroke adjustment rod with limit switches

- Manual lubrication

- Manual black gauge

- Standard V block punch

- Instruction manual

SPECIFICATIONS

- All dimensions are in mm.

-

Power supply 400/440 volts, 3 phase, 50 cycle.

Geard Machine: 1440 RPM / Ungeard Machine: 960 RPM - As day to day Improvements are contemplated for better performance of the machine, We are reserve the rights to alter the specifications without prior notice.

- All the machines undergo a through check-up by our expert engineers before dispatch to ensure their smooth and trouble free operation.

- Electricals are not under warranty.

TECHNICAL SPECIFICATIONS

| Model | Tonnage | Bending Cap. (In M.S., UTS 45 Kg / mm² | Table Length | Table Width | Clear Pass | Ram Stroke | Open Height | Throat Depth | Speed Approch Pressing Return | Power H.P. | Over all Diamensions (L x W x H) | Approx. Weight Kgs. |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MHPB 215 | 20 | 1.6 × 1500 | 2 × 1250 | 1500 | 125 | 1250 | 100 | 250 | 100 | 35-9-35 | 2 | 1800 × 1500 × 2000 | 1500 |

| MHPB 320 | 30 | 2 × 2000 | 3 × 1250 | 2000 | 125 | 1700 | 100 | 280 | 200 | 30-07-30 | 3 | 2300 × 1600 × 2000 | 2500 |

| MHPB 425 | 40 | 2 × 2500 | 3 ×1500 | 2500 | 170 | 2000 | 100 | 280 | 200 | 40-8-40 | 3 | 2700 × 1850 × 2050 | 3000 |

| MHPB 515 | 50 | 4 × 1500 | 5 × 1250 | 1500 | 170 | 1000 | 100 | 280 | 200 | 35-7-35 | 5 | 1800 × 1500 × 2000 | 2500 |

| MHPB 520 | 50 | 3 × 2000 | 4 × 1500 | 2000 | 170 | 1500 | 100 | 280 | 200 | 35-7-35 | 5 | 2300 × 1900 × 2200 | 3400 |

| MHPB 525 | 50 | 2.5 × 2500 | 3 × 2000 | 2500 | 170 | 2000 | 100 | 280 | 200 | 35-7-35 | 5 | 2850 × 1900 × 2200 | 3700 |

| MHPB 625 | 65 | 3 × 2500 | 4 × 2000 | 2500 | 170 | 2000 | 150 | 330 | 200 | 30-05-30 | 5 | 2850 × 1950 × 2350 | 3900 |

| MHPB 630 | 65 | 2.5 × 3000 | 3 × 2500 | 3000 | 170 | 2500 | 150 | 330 | 200 | 30-05-30 | 5 | 3350 × 1950 × 2350 | 4300 |

| MHPB 825 | 80 | 4 × 2500 | 5 × 2000 | 2500 | 170 | 2000 | 150 | 350 | 200 | 38-6-45 | 7.5 | 2850 × 2100 × 2350 | 4500 |

| MHPB 830 | 80 | 3 × 3000 | 4 × 2500 | 3000 | 170 | 2500 | 150 | 350 | 200 | 38-6-45 | 7.5 | 3350 × 2100 × 2350 | 5000 |

| MHPB 1025 | 100 | 5 × 2500 | 6 × 2000 | 2500 | 170 | 2000 | 150 | 350 | 200 | 38-6-45 | 7.5 | 2900 × 2200 × 2350 | 5600 |

| MHPB 1030 | 100 | 4 × 3000 | 5 × 2500 | 3000 | 170 | 2500 | 150 | 350 | 200 | 38-6-45 | 7.5 | 3400 × 2200 × 2350 | 6200 |

| MHPB 1040 | 100 | 3 × 4000 | 4 × 3000 | 4000 | 170 | 3000 | 150 | 350 | 200 | 38-6-45 | 7.5 | 4250 × 2200 × 2350 | 7000 |

| MHPB 1225 | 125 | 6 × 2500 | 8 × 2000 | 2500 | 220 | 2000 | 150 | 350 | 300 | 38-5-40 | 10 | 2750 × 2450 × 2600 | 6500 |

| MHPB 1230 | 125 | 5 × 3000 | 6 × 2500 | 3000 | 220 | 2500 | 150 | 350 | 300 | 38-5-40 | 10 | 3400 × 2450 × 2600 | 7000 |

| MHPB 1240 | 125 | 4 × 4000 | 5 × 3000 | 4000 | 220 | 3000 | 150 | 350 | 300 | 38-5-40 | 10 | 4150 × 2450 × 2650 | 8800 |

| MHPB 1625 | 160 | 8 × 2500 | 10 × 2000 | 2500 | 220 | 2000 | 150 | 350 | 300 | 35-6-40 | 15 | 2750 × 2500 × 2600 | 8200 |

| MHPB 1630 | 160 | 6 × 3000 | 8 × 2500 | 3000 | 220 | 2500 | 150 | 350 | 300 | 35-6-40 | 15 | 3400 × 2500 × 2600 | 8800 |

| MHPB 1640 | 160 | 5 × 4000 | 6 × 3000 | 4000 | 220 | 3000 | 150 | 350 | 300 | 35-6-40 | 15 | 4200 × 2500 × 2700 | 9800 |

| MHPB 2025 | 200 | 10 × 2500 | 12 × 2000 | 2500 | 220 | 2000 | 200 | 410 | 300 | 35-7-35 | 20 | 2850 × 2650 × 2700 | 8500 |

| MHPB 2030 | 200 | 8 × 3000 | 10 × 2500 | 3000 | 220 | 2500 | 200 | 410 | 300 | 35-7-35 | 20 | 3450 × 2650 × 2700 | 9500 |

| MHPB 2040 | 200 | 6 × 4000 | 8 × 3000 | 4000 | 220 | 3000 | 200 | 410 | 300 | 35-7-35 | 20 | 4200 × 2650 × 2800 | 10500 |

| MHPB 2530 | 250 | 10 × 3000 | 12 × 2500 | 3000 | 300 | 2500 | 200 | 410 | 300 | 35-6-40 | 25 | 3350 × 2650 × 2800 | 12000 |

| MHPB 2540 | 250 | 8 × 4000 | 10 × 3000 | 4000 | 300 | 3000 | 200 | 410 | 300 | 35-6-40 | 25 | 4350 × 2650 × 2800 | 13500 |

| MHPB 3030 | 300 | 12 × 3000 | 15 × 2500 | 3000 | 300 | 2500 | 200 | 410 | 300 | 30-06-35 | 30 | 3450 × 2750 × 2800 | 12000 |

| MHPB 3040 | 300 | 10 × 4000 | 12 × 3000 | 4000 | 300 | 3000 | 200 | 410 | 300 | 30-06-35 | 30 | 4250 × 2750 × 2900 | 15000 |

| MHPB 4030 | 400 | 16 × 3000 | 20 × 2500 | 3000 | 300 | 2500 | 250 | 500 | 300 | 30-05-35 | 40 | 3350 × 2900 × 3000 | 17000 |

| MHPB 4040 | 400 | 12 × 4000 | 16 × 3000 | 4000 | 300 | 3000 | 250 | 500 | 300 | 30-05-35 | 40 | 4300 × 2900 × 3000 | 18000 |

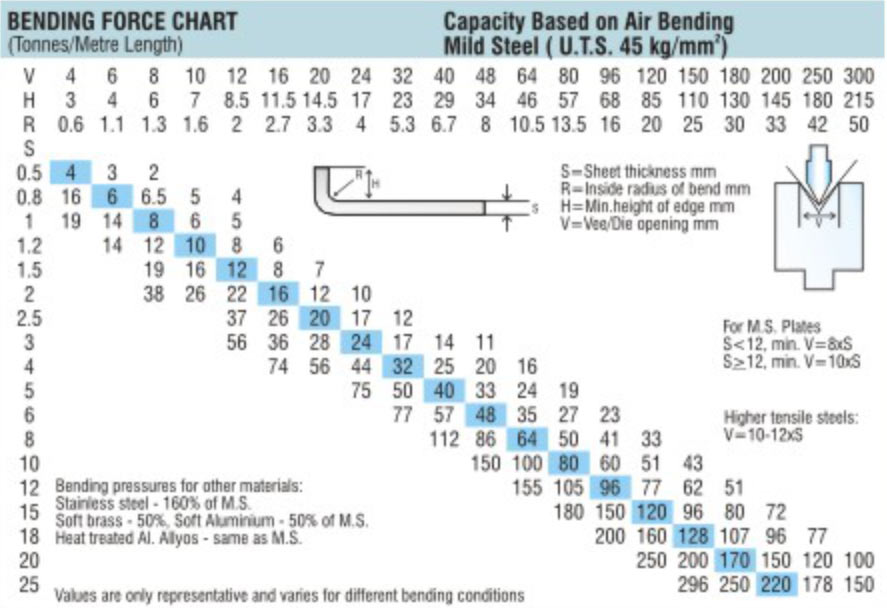

| Capacities rated for M.S. (U.T.S. 45kg/mm2). Bending Capacities started are only representative and not binding. Allow extra capacity for material inconsistencies, bending conditions. Rigth to change specification, features without notice reserved. Compliance with safety requirements as per local regulations is responsibility of the user. | |||||||||||||

OPTIONS :

- Goose Neck punch & other tooling (Drawing required)

- Electronic Stroke Counter

- NC Operated Back Gauge

- automatic Lubrication System