PROCESS

Product application that caters all these industries that fulfils your requirements.

RESEARCH & DEVELOPMENT

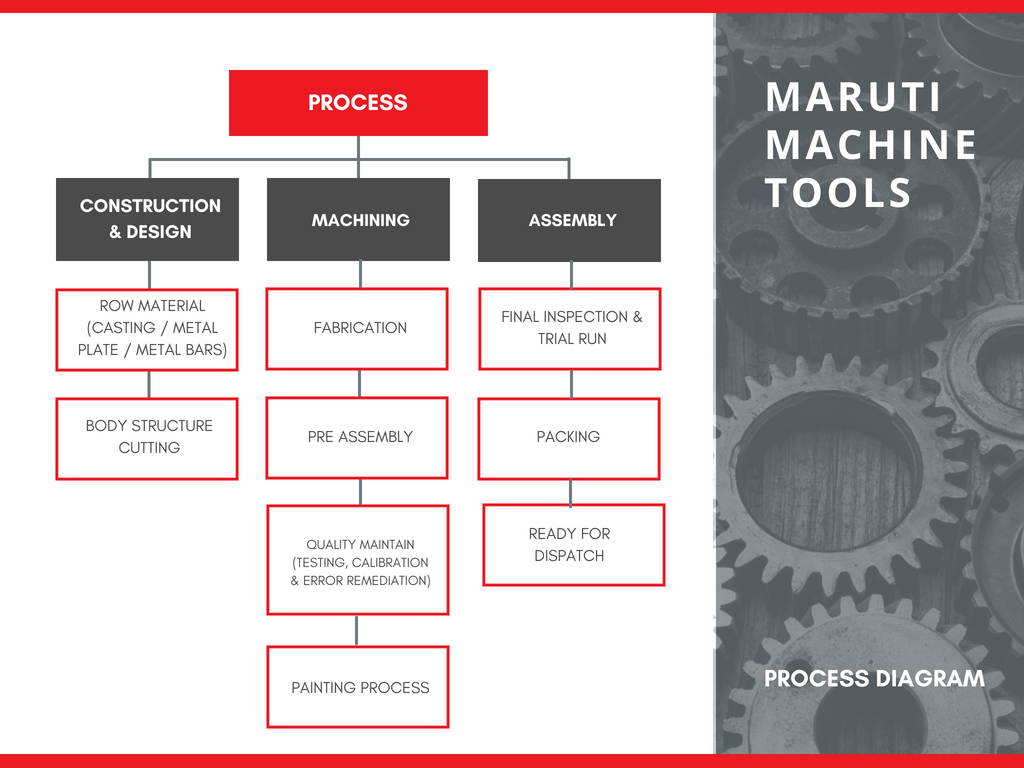

CONSTRUCTION & DESIGN

We, at Maruti Machine Tools, in an initial step attach enormous importance to know that how compatible are the construction and design to the modern conditions. Working closely with the construction engineers, designers play a crucial role in determining how best to harmonies form and function. Our engineering staff is the perfect complement to our customer’s creativity. We are able to assist in the design process of a project with our customers, to help reduce costs, shorten prototype lead-times, and help bring to life complexed innovative ideas.

SUPERIOR ENGINEERING AND MANUFACTURING

MMT engineering staff is a diverse group that understands our industry and its challenges. Most of our work is highly customized, as such, it requires out of the box thinking combined with great expertise and intellectual .The choice of materials and colors and positioning them is always the logical outcome of constructive teamwork. Often, the designers and engineers will take their inspiration from old drawings and compare them with the new technology. Ultimately, it is respect for the machinery making pioneers of the past that guarantees continuity at Maruti Machine Tools.

QUALITY MANAGEMENT

Quality is the hallmark of our business and we take a team approach throughout the organization, starting with engineering and ending when it leaves our facility. As a part of our process we meticulously and without exception perform first piece article inspections, and seek pre-production samples approval from our customers. The advanced scientific methods are used including computer simulations, drawing analysis and tests designed to show how the machines behave under extreme practical, everyday conditions. The use of high-durability, performance and quality metal-working machines are the most important point of the sturdiness. Our quality staff is following closely the events and related seminars regularly and pay attention as much as possible to take part in these events.

Details such as guides, shafts, bearings or all other matters are examined, calculated and developed for potential sources of error from the earliest phases of development. All staff analyze the problems and errors that occurred in the previous projects and take in consider the feedbacks from the market and focus on their business afterwards. The result is, each product which sold under MMT name will continue to run years and years and protect the same performance and durability

ASSEMBLY

RESEARCH & DEVELOPMENT

We have a production line concept that offers high precision and high efficiency with our advanced:CNC Lathe Machine, Heavy Duty Lathe Machine, Milling Machines, Shapping Machines, MIG Welding Machine, Horizontal Boring Machine

We process the main body and other parts of our machines with high sensitivity, time studies, continuous machining in our manufacturing plant. We are establishing a high-efficiency business association by stating that our suppliers have a quality and faultless production understanding like ours.

SOURCE TECHNOLOGIES

Our combination of a stream line process, engineering experience and the use of the same software platform as our customers, allows us to be the industry leader in rapid prototyping. Our turnaround times range from 1 to 5 days depending on complexity. We understand the importance of speed to market, but we also understand that quality is just as important. As a machine manufacturer; we are also aware that one foot of machine production is high-capacity machining and the other foot is applications of advanced welding technology. All of our employees at our welding workshop attend the welding training conducted by the company and closely follow the day’s technology.

PAINTING WITH POWDER COATING

Frame painting of our machines is carried out in our factory with the “wet paint technology”. Sheet-plate parts are being painted with the “dry paint technology”. With our own in-house powder coating line we are able to control the high level finishes our customers have come to expect. Imagination is the only limiting factor to the array of colors we can provide. Our finishes range from matte, textured to high gloss.

FINAL CONTROL AND TESTING

Our finished machines have passed through the testing process where the quality of the mechanical working system and capacity, hydraulic tightness, electronic precision and general appearance are thoroughly checked by our staff. The machines that meet the necessary conditions are ready for sale.